For engineers, there isn’t much time to waste on tedious, manual processes. When a project takes off, it is typical to focus on, “practical and technical details and lose sight of the broader regional context.” However, review processes are critical for quality assurance and impact analysis. Engineering teams can’t afford to neglect the big picture.

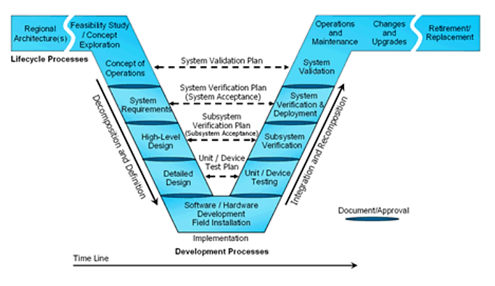

Over time there have been several process models, however, the “V” model was first developed in the 1980s and best reflects the industry standard of the engineering process. This model shows the process of project development and moves from feasibility studies through the retirement of the product or system.

Photo Credit: North Dakota Department of Transportation

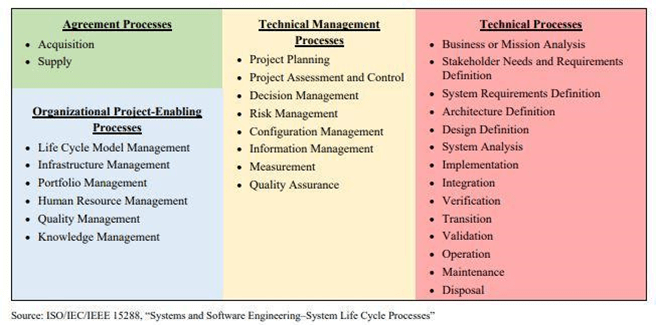

In 1994, ISO/IEC 15288 planning began to cover systems engineering processes and life cycle stages (processes). The four categories defined are defined as being technical, project, agreement, and enterprise. However, ISO 15288 is essentially derived from several hundreds of activities.

According to MITRE, expected outcomes upon successful implementation of a review process include:

- Quality management policies and procedures are defined

- Definition of quality objectives

- Accountability and authority for quality management are also defined

- The status of customer satisfaction is monitored

- Appropriate action is taken when quality objectives are not achieved

Necessary Steps to Prepare for a Standard Engineering Review Process

Before implementing a review process, consider some of the following preliminary steps to ensure your method makes the most sense for your needs.

Establish criteria for success

Defining what success looks like will provide you with direction. As the engineering team begins to develop a solution, success criteria may shift. Criteria for success should be developed based on research and background knowledge.

Gather pertinent information

Collect information to ensure that all factors have been considered in regard to the problem at hand. This leads engineering teams to problem-solve through all possible needs and thus supports the direction toward the solution.

Establish documentation process

Whether it’s done manually through spreadsheets or with a tool, documentation is important for traceability. However, manual documentation is often error-prone due to the complexity, typically as a result of the use of various engineering tools and artifacts.

SECollab: SodiusWillert's Solution for Engineering Review Processes

The challenge of meeting standard process requirements can be overwhelming and time-consuming for many engineering teams. Our team has developed a powerful tool to provide unified designs from multiple tools within the same environment.

When you partner with SodiusWillert, traceability and communication are improved across the entire team. If your team is ready for a hassle-free formal review process, traceability, and access controls, contact us today.

Leave us your comment